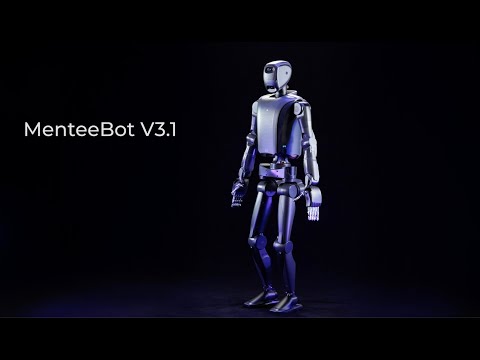

Just when you thought the humanoid robot party couldn’t get more crowded, Mentee Robotics elbows its way to the front with a teaser for its new MenteeBot V3.1. The Israeli startup, co-founded by Mobileye CEO and serial entrepreneur Amnon Shashua, is showcasing a machine built from the ground up for the grueling reality of industrial work, boasting a payload capacity of up to 25 kg (55 lbs).

The V3.1 stands 175 cm (5'9") tall and weighs in at a solid 70 kg (154 lbs). But the most telling feature isn’t its spec sheet—it’s the company’s obsessive focus on vertical integration. Mentee Robotics claims its in-house development of everything from proprietary actuators and precision motor drivers to robotic hands with motor-based tactile sensing is the key to cracking the “Sim2Real” gap. This notorious problem in robotics refers to the difficulty of transferring AI learning from clean, predictable simulations to the chaotic real world.

To keep the robot punching the clock, Mentee has designed a hot-swappable battery system, aiming for uninterrupted 24/7 operation. With 40 degrees of freedom and a walking speed of 1.5 m/s, the bot is clearly intended for dynamic environments like logistics and manufacturing floors. The company, which came out of stealth in 2024, is targeting the first quarter of 2025 for a production-ready prototype.

Why is this important?

While companies are racing to demo humanoids folding laundry, Mentee Robotics is doubling down on the unglamorous but critical industrial sector. Its “full-stack” approach is a direct shot at the reliability and deployment issues that have kept most humanoids in the lab. By controlling every component, from the motors to the AI, Mentee believes it can achieve the robustness needed for scalable, real-world use. If they can truly minimize the Sim2Real gap, they won’t just be building another humanoid; they’ll be building a viable robotic workforce for a market projected to explode in the coming years.